We have five reasons to replace hand stretch wrapping pallets with a semi-automatic or automatic stretch wrapping system for your pallet load containment applications. Whether you came from custom warehousing or other industrial buildings with stretch wrap equipment or you have seen them through advertisements – here are the top considerations when reviewing this investment.

Consistent and Uniform Packaging

An operator who wraps pallets with hand wrap stretch film is not able to wrap every load exactly the same way, time and time again. A load wrapped by one operator Monday morning will not be wrapped the same way as another operator on Friday afternoon. Pallet wrapping with a stretch wrap machine eliminates this issue. This is important for consistent load containment and film usage. Because film is priced per pound, you want to make sure your operation is able to budget as closely as possible per piece leaving your dock.

Wrapping a pallet using a stretch wrap machine also produces a clean professional finished product. Pallet wrapping with hand wrap can look rather erratic and uneven. Hand wrapping usually means there is more film on the pallet as well – obstructing the view to labels or products. The look of your pallet load on your customer’s floor must project the professional image you want for your company. Pallet wrapping with a stretch wrap machine eliminates this issue.

Employee Safety and Training

Hand wrapping pallets is an extremely difficult job when repeated throughout the day, and it is a common source of employee back injuries whether done correctly or incorrectly. It would come to now surprise operators are more susceptible to injury by quick twisting movements while maneuvering film below and above the waistline. Many accidents and work-related injuries are caused by hand-wrapping pallets. Review OSHA (Occupational Safety & Health Administration) stretch wrapping guidelines as a reference.

There is a right way and a wrong way to wrap a pallet with hand wrap from a technical perspective as well. Applied incorrectly, hand wrap may crush the product or allow the product to shift during transport. Employee turnover or multiple operators means you must continually train employees on how to correctly wrap the loads to ensure customer satisfaction while ensuring they do not injure themselves. Pallet wrapping with a stretch wrap machine gives consistent output at a much safer rate.

Film Savings

Oftentimes, our industrial packaging supplier sees operators applying more film than necessary to a pallet with the intention of creating better load containment. However, this methodology is money wasted. We also see how hand wrapping can create situations where pallets need to be re-wrapped because there wasn’t enough film or there is more film than needed. Because film is priced by the pound it’s important to be consistent with the application. Our service technicians will key in a cold seal packaging machine so it has the perfect load containment at the lowest cost possible, and your sales person matches the most efficient film to the machine to help aid in further cost savings.

Load Integrity and Damage Control

No one likes hand wrapping. At some point, the “good enough” syndrome takes over. Knowing what is required to keep your product unitized during shipping, and while it is on your customer’s floor, is essential in setting your stretch wrapping specifications for your operators to follow. When an employee is hand wrapping pallets the responsibility of meeting minimum tension requirements is left up to them. Fatigue, ignorance, training, or lack of motivation can affect the employee’s “good enough” point resulting in potential complaints or damage due to poorly wrapped product.

As employees deal with the difficulty of hand wrapping the goal becomes just wrapping it enough to get it out the door. Wrapping the load to eliminate damage during transit and at your customer’s warehouse becomes secondary. Pallet wrapping with a stretch wrap machine eliminates this issue as it wraps the same way every time reducing the potential of a pallet being damaged during transit.

Quality Control

By definition, hand wrapping a pallet manually prevents you from obtaining any type of repeatability. Multiple operators, time of day, fatigue and many other variables prevents any type of QC standards. Pallet wrapping with a stretch wrap machine allows you to either eliminate, or preset these variables. This ensures repeatability, allowing loads to be wrapped to a set quality standard.

In Conclusion

Stretch wrap is a subject filled with savings whether you are hand wrapping or considering a stretch wrap system. In today’s market you can start seeing an acceptable ROI when wrapping one or more pallets an hour during a shift. From entry-level to fully automatic, we have a solution for every application as one of the top packaging suppliers. We can also show demonstrations of the equipment we sell.

One of our most cost-effective and popular options is

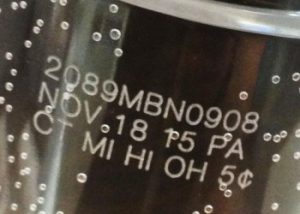

One of our most cost-effective and popular options is  This system was designed to provide high quality, permanent marks onto aluminum cans for the craft brew industry (and beverage industry as a whole). Breweries, much like food manufacturers, are looking for ways to eliminate ink chemicals, reduce mess, improve mark appearance, and reduce the cost per mark. With vector-quality marking and the elimination of solvent and ink consumables into the waste stream the

This system was designed to provide high quality, permanent marks onto aluminum cans for the craft brew industry (and beverage industry as a whole). Breweries, much like food manufacturers, are looking for ways to eliminate ink chemicals, reduce mess, improve mark appearance, and reduce the cost per mark. With vector-quality marking and the elimination of solvent and ink consumables into the waste stream the  We understand not everyone has an in-line conveyor system, that’s where Digital Design’s Evolution Handheld really comes in handy. While working with Digital Design’s other leading printhead models, this hand-held is perfect for the company that needs flexibility in movement without compromising the quality of marking.

We understand not everyone has an in-line conveyor system, that’s where Digital Design’s Evolution Handheld really comes in handy. While working with Digital Design’s other leading printhead models, this hand-held is perfect for the company that needs flexibility in movement without compromising the quality of marking.