The holidays are upon us and those UPS, FedEx and DHL deliveries are about to stack up quickly. It is estimated 40% of the worlds plastic waste comes from packaging alone – whether it be food, electronics, medical, home goods or other. But, sustainability in industrial packaging isn’t just about using less or finding more recyclable options – it encompasses a 360 degree view from where the raw materials originate all the way to a community’s disposal infrastructure. We put together the “ABCs of Sustainable Packaging Terms” to help provide a broader perspective to this growing topic.

Before we get into it, let’s discuss some of the pitfalls when it comes to sustainability in an industrial packaging wholesaler. Colony strives to be transparent and upfront when it comes to what is and is not sustainable packaging and our role as your distributing partner in it. We don’t fit the expectation into the industry, instead we present the real facts backed by science to support the expectations. Here we highlight products and claims which as packaging experts we don’t consider fully sustainable options.

- Biodegradable Plastics: While biodegradable plastics have gained popularity for their potential to break down more quickly than traditional plastics, they often require specific conditions, such as industrial composting facilities to decompose fully. In the absence of these conditions, which is more common than not, materials will still persist in the environment, contributing to pollution.

- Single-Use Compostable Packaging: Similar to biodegradable plastics, compostable packaging items like plates, cups, and cutlery need specialized composting facilities to break down properly. When disposed of in regular waste streams or landfills, they will not biodegrade as intended.

- Paper Packaging with Non-Recyclable Coatings: Some paper packaging products come with non-recyclable coatings or laminates that make them difficult to recycle. These coatings can contaminate recycling streams and hinder efforts to reduce waste.

- Packaging with Excessive Greenwashing: Some manufacturers and top packaging suppliers may overstate the environmental benefits of their products through greenwashing. This can mislead consumers into thinking they are making sustainable choices when, in fact, the product’s overall impact on the environment remains high. An example of this could be products with biodegradable additives – the language sounds great but the reality is not.

- Heavy, Bulky Packaging: Packaging materials that are unnecessarily heavy or bulky can result in higher transportation costs and increased emissions. While they may not explicitly market themselves as sustainable, their inefficiency in resource use contradicts sustainability goals.

- Products Lacking Certification or Transparency: Packaging products claiming to be eco-friendly should ideally have certifications or clear documentation to support their sustainability claims by trusted third party sources. Lack of transparency and verifiable information can raise doubts about a product’s true environmental impact.

- Excessive Packaging: While not limited to a specific material, the practice of over-packaging products can lead to unnecessary waste and resource consumption. Companies may use excessive packaging to enhance product aesthetics or safety, even if it’s not environmentally justified. Colony Packaging excels in package conversion to reduce this waste.

Evaluating your packaging materials with three things in mind when it comes to sustainability goals on a very basic level could include:

- Use packaging which decreases or eliminates damage rates

- Reduce overall packaging to the greatest extent possible

- Consider curbside recyclable options to make it easier on the consumer to recycle materials

Sustainability in packaging can be quite extensive – looking for additional ideas? Here are our industrial packaging supplies company ABCs of Sustainability:

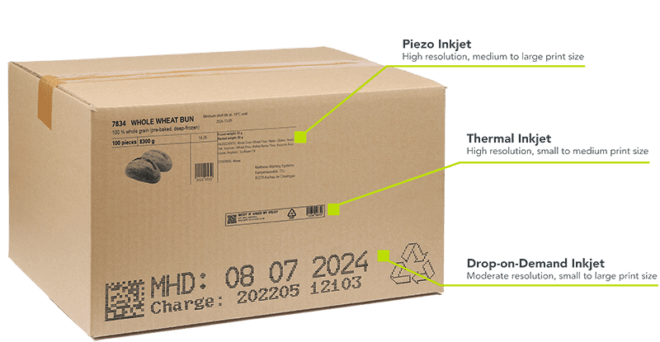

A – Analytics: Colony Packaging & Machine will help you make better decisions with data-driven insights for optimizing packaging processes as it applies to labor savings, decreased material usage, increased material effectiveness, overall safety and sustainability concerns.

B – Biodegradable: Colony can help distinguish packaging materials that decompose naturally versus smoke and mirrored marketing so you get exactly what you think you are getting.

C – Circular Economy: A system aimed at eliminating waste through the continual use of resources.

D – Durability: Colony focuses on the ability of packaging to withstand the rigors of transport and storage to decrease or eliminate damage or returns. This process is naturally focused in sustainability, but with an added bonus of recognizing materials that are also physically sustainable can increase this effort two-fold.

E – Eco-friendly: Colony can work with you to recognize the best packaging that does the least harm to the environment from raw material sourcing, labor considerations to the manufacturing process to the ability for the end user to recycle the material successfully curbside.

F – Footprint Reduction: Whether it be increased packaging equipment efficiencies or custom warehousing for power savings or strategies to minimize environmental impact through decreased material usage, Colony has multiple avenues to explore an overall footprint reduction.

G – Green Certification: Colony can provide documentation regarding standards that verify sustainable practices in packaging from manufacturers when available.

H – Hazardous Materials Compliance: SDS/Tech data is always available from Colony’s vendor partners to ensure packaging meets safety regulations for hazardous substances.

I – Innovation: Colony is very focused on new technologies and materials for sustainable packaging solutions and bringing those solutions to our customers for consideration.

J – JIT (Just-in-Time) Delivery: We reduce deliveries from our manufacturing partners and to our customers by offering a large stocking program and dedicated, scheduled runs to best decrease unnecessary fuel usage.

K – Kraft Paper: A key sustainable choice which has quite a lot of possibility through Ranpak’s extensive line of kraft paper converting equipment. Kraft paper is a great resource for blocking, bracing, cushioning, and void fill.

L – Lifecycle Assessment: Work with Colony to evaluate the environmental impact of packaging from creation to disposal. This includes raw material sourcing, the manufacturing process, deliverability, curb-side recyclability and more.

M – Minimalism: Colony promotes using the least amount of materials necessary to achieve functionality while decreasing damage rates. Continued innovation within packaging materials makes this possible.

N – Natural Materials: Colony can help distinguish fact from fiction when it comes to sourcing packaging from organic, renewable resources.

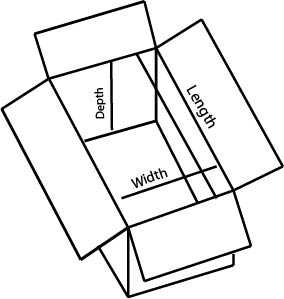

O – Optimized Design: Colony offers a large knowledge base across industries to streamline packaging to reduce materials and waste.

P – Post-consumer Recycled Content: Utilizing materials that have been recycled after consumer use is a great way to get one-time use materials out of the landfill and back into the supply chain – Paragon offers a patented PCR stretch film which meets these qualifications.

Q – Quality Assurance: Ensuring sustainable packaging meets high standards without compromising safety can be done through third party evaluations, but the best route is through direct conversations with us at Colony and our specific vendor partners supplying your material – the information will be more accurate, complete and goal-oriented.

R – Reusable Packaging: Colony can connect you with designs that allow for multiple uses before disposal and also reusable closed-chain packaging containment solutions like pallet wraps, containers, and more.

S – Sourcing: Work with us to outline your ideal responsible procurement methods from sustainable sources, and we at Colony can help present options which get you there.

T – Transparency: Our team at Colony wants to work alongside you to reach clear communication about materials and processes used/required in your packaging.

U – Upcycling: We love a good repurposing of packaging materials for new uses and so do your customers.

V – Value Chain Optimization: Improving the efficiency of packaging processes throughout the supply chain.

W – Waste Reduction: Colony works with our customers on strategies aimed at minimizing packaging waste – in turn this should lead to decreased damage and faster outputs.

X – X-factor Sustainability: This can include unique sustainable features that differentiate products in the market – to help share that information with your customer base consider adding an interactive QR code to help elevate your message.

Y – Yield Improvement: A key factor Colony is focused on is enhancing the efficiency of material use in your packaging.

Z – Zero Waste: A commitment to eliminating waste in packaging production and disposal.

[wpforms id=”10226″ title=”true”]

Paragon Films has been working hard on creating a stretch film with greater percentages of PCR – post consumer recycled content. With patents in hand they are the only stretch film on the market truly living up to the more modern take on sustainability goals delivering 25% PCR in the new

Paragon Films has been working hard on creating a stretch film with greater percentages of PCR – post consumer recycled content. With patents in hand they are the only stretch film on the market truly living up to the more modern take on sustainability goals delivering 25% PCR in the new

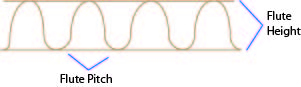

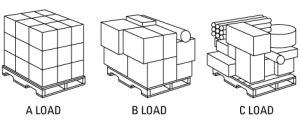

Stretch film comes in varying gauges, lengths, chemical make-ups, colors and can be used in numerous applications. Not all stretch film works on all loads and for all applications. One interesting variable and starting point for stretch films is deciding between blown or cast manufacturing processes. But first, if you are unsure of

Stretch film comes in varying gauges, lengths, chemical make-ups, colors and can be used in numerous applications. Not all stretch film works on all loads and for all applications. One interesting variable and starting point for stretch films is deciding between blown or cast manufacturing processes. But first, if you are unsure of