From food and beverage, personal and household goods, to pharmaceutical and medical, we understand the challenges of the consumer packaged goods industry. As an industrial packaging company, we have the high-speed laser and inkjet printing equipment, high-adhesion inks —including those meeting FDA regulations—needed to craft a reliable and accurate marking and coding solution as part of your overall track-and-trace system.

Beverage

Bottles and Cans

The only thing more important than easy to read and accurate “best by” expiry date, batch, and lot codes is making sure your line doesn’t stop. Colony Packaging & Machine can help you with both. Matthews’ laser coding machines maximize uptime by producing vector-quality codes at high speeds and help you meet the high production demands of the beverage industry without sacrificing quality.

The only thing more important than easy to read and accurate “best by” expiry date, batch, and lot codes is making sure your line doesn’t stop. Colony Packaging & Machine can help you with both. Matthews’ laser coding machines maximize uptime by producing vector-quality codes at high speeds and help you meet the high production demands of the beverage industry without sacrificing quality.

Substrates and applications include:

- Glass bottles

- Plastic bottles

- Aluminum cans

- Barcoding

- Lot, batch and ID coding

- Branding

Food

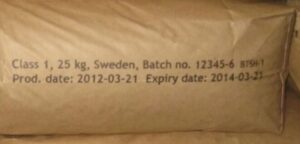

Bag Marking

Bag marking technology for consumer packaged goods or industrial applications that require text, graphics, or codes with large or small characters. Our industrial printers have the capability to print on paper, plastics (polypropylene, mylar, PET) and other substrates…we can solve your toughest bag marking challenges.

Bag marking technology for consumer packaged goods or industrial applications that require text, graphics, or codes with large or small characters. Our industrial printers have the capability to print on paper, plastics (polypropylene, mylar, PET) and other substrates…we can solve your toughest bag marking challenges.

Get high-contrast, high-resolution marks in a wide array of colored porous and non-porous inks, including MEK and inks with FDA-approved ingredients.

Substrates and applications include:

- Paper bags

- Plastic film bags

- Rigid plastic bags

- Serialization

- Lot, batch and ID coding

- Branding

Glass Bottling and Jars

Matthews offers highly reliable inkjet options to give you superior quality while keeping up with the demands of high-speed printing. Our industry expertise will help you find the right solution to keep your line up and running, with an in-house engineering team to design an integration solution that fits your line’s unique needs.

Matthews offers highly reliable inkjet options to give you superior quality while keeping up with the demands of high-speed printing. Our industry expertise will help you find the right solution to keep your line up and running, with an in-house engineering team to design an integration solution that fits your line’s unique needs.

Substrates and applications include:

- Glass containers

- Glass jars

- Windows for home and auto

- Product identification

- Lot, batch and ID coding

- Branding

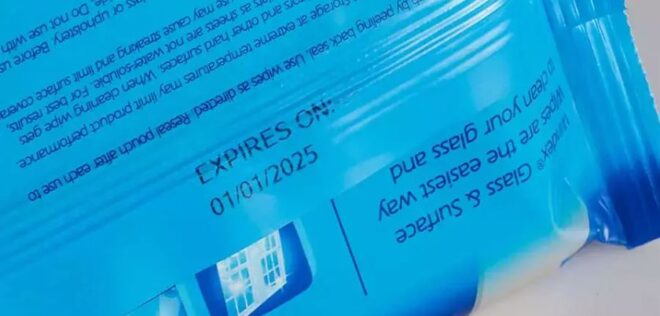

Plastic

Matthews Marking Systems offers highly reliable marking technologies for plastic packaging and product manufacturers, including drop-on-demand (DOD) printers, thermal inkjet printers, and automatic labeling machines. Matthews’ years of experience in the plastic industry allow them to understand the challenges you are facing, and present you with proven solutions, minimizing your risk.

Matthews Marking Systems offers highly reliable marking technologies for plastic packaging and product manufacturers, including drop-on-demand (DOD) printers, thermal inkjet printers, and automatic labeling machines. Matthews’ years of experience in the plastic industry allow them to understand the challenges you are facing, and present you with proven solutions, minimizing your risk.

Thanks to the wide variety of fast-drying non-porous inks in a rainbow of colors, you can get a quality mark, whether you’re printing simple date, time, and lot codes or higher resolution logos and graphics.

Substrates and applications include:

- Pipe

- Thin and rigid film

- Shrink wrap

- Plastic clamshells

- Plastic pouches

- Building products

- 2D codes

- Product identification

- Lot, batch and ID coding

- Branding

Personal and Household Goods

Matthews offers a wide range of options for everything in the personal and home goods realm including previously mentioned categories plastic and glass. Matthews also specializes in Corrugate Case Coding.

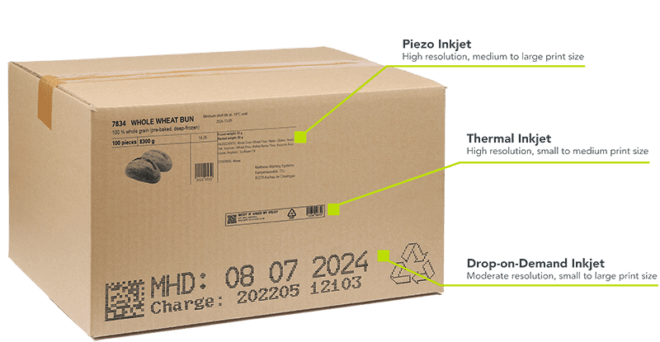

Drive Overall Equipment Efficiency (OEE)

Take advantage of significant costs savings and superior flexibility by printing on corrugated cases and cartons. Marking directly onto your corrugated boxes costs a fraction of labels and pre-printed boxes. You can print in native heights of 3/32″, 3/16″, 1/4″, 1/2”, 1”, 2”, 4”, 5″ and even larger when stitching printheads, which provides significant cost savings and superior flexibility on a myriad of box sizes and shapes.

Take advantage of significant costs savings and superior flexibility by printing on corrugated cases and cartons. Marking directly onto your corrugated boxes costs a fraction of labels and pre-printed boxes. You can print in native heights of 3/32″, 3/16″, 1/4″, 1/2”, 1”, 2”, 4”, 5″ and even larger when stitching printheads, which provides significant cost savings and superior flexibility on a myriad of box sizes and shapes.

Get Exactly What You Need for Your Production Line

High resolution barcodes, 2D codes, lot codes, expiry dates, and more are efficiently handled with our thermal inkjet printing solution. Branding, large graphics and fonts, and multiple lines of crisp text are ideal applications for our piezo inkjet printing solution. Simple alphanumeric lot and batch codes, expiry dates, and low-resolution graphics or fonts are perfectly printed with our drop-on-demand printing solution. Any of our marking solutions will positively impact your bottom line and seamlessly integrate into your production operation.

Applications:

- Traceability initiatives/programs

- Barcodes (GS1-128, GS1 DataBar, EAN-8/13, UPC-A, ITF/ITF-14, Code 39/128)

- 2D codes (GS1-Data matrix, Data matrix, QR and Micro QR code)

- Lot, batch and ID coding

- Branding

- Retail shelf graphics

- Distribution logistics

- Low-resolution alphanumeric codes

Additional Consumer Goods Marking and Coding Options

Matthews also offers options for the pharmaceutical and medical industries and corrugated packaging options for secondary packaging applications. We offer a full analysis of the substrates your company uses, the production speed and code requirements to offer a Matthews solution that exceeds your expectations.

Why choose us? Why choose Matthews?

As a leading distributor for Matthews Marking our team has the training, access and ability to work with your departments on a personalized level to guarantee success from the brainstorming stage to implementation and beyond. We use our broad industry knowledge to fill in blind spots and elevate your goals for ultimate success. We work with Matthews and their vast engineering team to keep projects on track and moving in the right direction. Their decades of specialized experience matched with our personalized, industry specific knowledge gives you a one-two punch.

Our V-Series marking systems are engineered for the harsh, challenging environments typically found in rubber processing and tire manufacturing. They deliver proven reliability for small and large character marking on rubber and tires. Our VOC-free white ink, “disappearing” ink, and other specialized inks for rubber are engineered in house and deliver the best adhesion and mark quality in the industry today.

Our V-Series marking systems are engineered for the harsh, challenging environments typically found in rubber processing and tire manufacturing. They deliver proven reliability for small and large character marking on rubber and tires. Our VOC-free white ink, “disappearing” ink, and other specialized inks for rubber are engineered in house and deliver the best adhesion and mark quality in the industry today. With Matthews’

With Matthews’

With the industry’s most reliable inkjet printing technology and the broadest range of inks for the metal industry, Matthews is your go-to provider for metal marking. They provide turnkey and custom-engineered solutions for placing any kind of mark on nearly any type of metal at speed and with rock-solid reliability.

With the industry’s most reliable inkjet printing technology and the broadest range of inks for the metal industry, Matthews is your go-to provider for metal marking. They provide turnkey and custom-engineered solutions for placing any kind of mark on nearly any type of metal at speed and with rock-solid reliability.

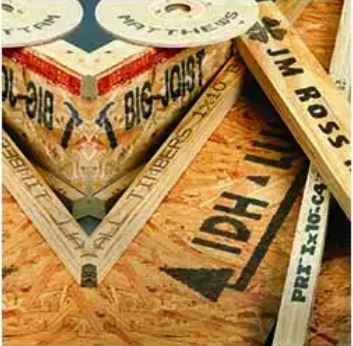

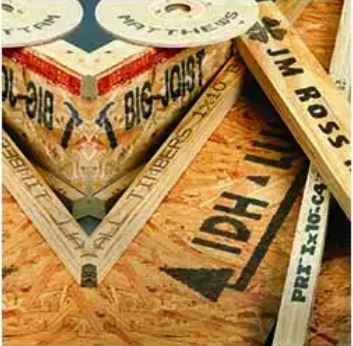

Clearly marking your wood products gives you a competitive edge in the marketplace, and we offer solutions representing the best way to help you do that. From identifying your product with large, bold images of your brand to accurately printing specifications, association trademarks, mill numbers and more, our comprehensive solutions help you every step of the way. The Matthews Marking workhorse DOD printer lineup is the industry leader and provides your production with reliable operation and the maximum possible uptime.

Clearly marking your wood products gives you a competitive edge in the marketplace, and we offer solutions representing the best way to help you do that. From identifying your product with large, bold images of your brand to accurately printing specifications, association trademarks, mill numbers and more, our comprehensive solutions help you every step of the way. The Matthews Marking workhorse DOD printer lineup is the industry leader and provides your production with reliable operation and the maximum possible uptime. Achieve high quality marks with unprecedented control and gain a competitive advantage with the most reliable, versatile marking and coding solutions available for the steel and metal industry. Easily integrate with existing or new production lines at scale.

Achieve high quality marks with unprecedented control and gain a competitive advantage with the most reliable, versatile marking and coding solutions available for the steel and metal industry. Easily integrate with existing or new production lines at scale. Our coding and marking systems ensure your plastic and metal pipe is easily identifiable over its life cycle, with high-quality prints that last. Your customers need crisp, clear marks that include material type, manufacturer’s name, size, pressure rating/relevant manufacturing standard, and any other information that has significant meaning to them and we can make it happen.

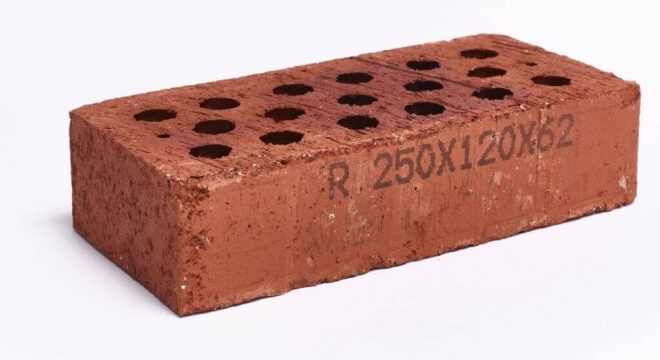

Our coding and marking systems ensure your plastic and metal pipe is easily identifiable over its life cycle, with high-quality prints that last. Your customers need crisp, clear marks that include material type, manufacturer’s name, size, pressure rating/relevant manufacturing standard, and any other information that has significant meaning to them and we can make it happen. Matthews Marking Systems offers a wide range of reliable marking and coding technologies for porous and non-porous surfaces in the stone processing industry. With many years of industry experience and the expertise of their in-house engineering team, we have solutions for direct printing of your product as well as solutions for marking pallet goods, big bags, and

Matthews Marking Systems offers a wide range of reliable marking and coding technologies for porous and non-porous surfaces in the stone processing industry. With many years of industry experience and the expertise of their in-house engineering team, we have solutions for direct printing of your product as well as solutions for marking pallet goods, big bags, and

Ranpak’s goal when they first opened in 1972 was to create the first environmentally responsible packaging material to effectively protect products during shipment. Ranpak is made from virgin and recycled kraft paper which gives it extra strength when it comes to packaging your materials and makes it 100% recyclable. Other cushioning paper that is made with higher percentages of recycled content tends to flatten and tear easier due to weaker fiber structure. Paper with higher rates of recycled content also have an increase in rejection at the recycling center due to higher rates of contamination within the product. Ranpak uses clean, unaltered processes so the paper will biodegrade in the correct environment in as little as three months. The paper also ships in flat, compact bundles so it uses less freight space to get from point A to point B versus other forms of cushioning.

Ranpak’s goal when they first opened in 1972 was to create the first environmentally responsible packaging material to effectively protect products during shipment. Ranpak is made from virgin and recycled kraft paper which gives it extra strength when it comes to packaging your materials and makes it 100% recyclable. Other cushioning paper that is made with higher percentages of recycled content tends to flatten and tear easier due to weaker fiber structure. Paper with higher rates of recycled content also have an increase in rejection at the recycling center due to higher rates of contamination within the product. Ranpak uses clean, unaltered processes so the paper will biodegrade in the correct environment in as little as three months. The paper also ships in flat, compact bundles so it uses less freight space to get from point A to point B versus other forms of cushioning.