Company Background

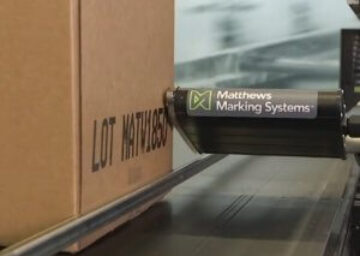

Matthews Marking Systems solves industrial and consumer packaged goods marking and coding challenges throughout the whole production line, from out-of-the-box products to custom engineered systems. Customers can count on Matthews for effective solutions that add value to the product line.

Introducing MPERIA CO2 by Matthews Marking

Featured Solution: MPERIA by Matthews

Simple, Sophisticated, Efficient

Your team can select and verify messages in seconds, reducing marking errors and saving labor hours. Customize the controller to fit your specific needs, keeping integration costs low. Control one printhead or multiple across your production floor with one interface. Integrate the platform seamlessly with your enterprise systems, regardless of manufacturer.

User-Friendly Operation

Manage all your equipment, from printers to barcode readers, scales, and actuators, through a single user interface. Simplify operator and maintenance personnel training, reducing equipment touches and potential errors. Guarantee system redundancy with automated backup print equipment activation when necessary. Seamlessly coordinate marking data with ERP, WMS, PLCs, or big data systems for streamlined automation.

Streamlined Integration

Integrate effortlessly into your existing environment without custom software or server hardware. Connect with your current enterprise systems and legacy equipment, eliminating the need for third-party control software. Expand your operations and maximize your investment with ease.

MPERIA 8″ Controller

The MPERIA 8″ is the most compact controller in the MPERIA product line. This controller manages one printing technology. Upgrades are available that allow for expanding functions including the number of controlled devices.

- 8″ (203mm)

- IP55 rated

- Controls one print technology

MPERIA 12″ Controller

The MPERIA Standard has the capability to support all printing technologies for simultaneous print control and is ideal for primary, secondary, and tertiary marking and coding. Upgrades allow for a virtually unlimited number of printing devices and functionality.

- 12″ (304mm)

- IP40 rated

- Controls multiple print technologies

MPERIA 12″ Enclosed

The MPERIA Standard Enclosed has the capability to support all printing technologies for simultaneous print control and is ideal for primary, secondary, and tertiary marking and coding. Upgrades allow for a virtually unlimited number of printing devices and functionality.

- 12″ (304mm)

- IP54 rated

- Controls multiple print technologies

MPERIA 15″ H.E.

The MPERIA Standard H.E. has the same capability as the MPERIA Standard, and offers a 15” touchscreen in an IP65 stainless steel enclosure making it suitable for harsh environments.

- 15″ (381mm)

- IP65 stainless steel

- Controls multiple print technologies

MPERIA OEM

Optimized for machine builders wanting to integrate a robust, reliable, and cost-effective marking and coding solution in their production lines.

- Remote control GUI via VNC or MPERIA creator

- Wall or panel mount options

Marking and Coding Solutions

VIAJet L-Seriea

Providing extrodinary quality in a thermal inkjet printers great for variable data, QR and 2D codes, and more at unbeatable speeds.

VIAJet T-Series

Includes fade resistant inks on porous surfaces giving this thermal inkjet printer the durability needed across industries.

VIAJet V-Seires

A large and small drop-on-demand (DOD) valve marking system specifically designed for your demanding production lines.

Matthews offers a variety of inks which are matched between substrate and equipment. In this blog post learn how they work with your application in determining the right ink.

Featured Marking and Coding Blog Posts

Case Studies

FAQs

-

What is the MPERIA Controller and how does it improve marking and coding processes?

The MPERIA Controller is a cutting-edge solution designed to streamline marking and coding operations. It allows you to switch messages in seconds, centralize coding control, and improve mark quality on your production lines. By offering a user-friendly interface, automation capabilities, and seamless integration, the MPERIA Controller significantly enhances efficiency and reduces errors.

-

Can the MPERIA Controller integrate with our existing equipment and systems?

Yes, absolutely! The MPERIA Controller is highly flexible and can integrate smoothly into your current environment. No custom software or server hardware is required, ensuring seamless connectivity with your enterprise systems and legacy equipment, regardless of the manufacturer.

-

How does the MPERIA Controller simplify operator training and reduce errors?

The single user interface of the MPERIA Controller streamlines equipment control, making it easy for operators to manage printers, barcode readers, vision systems, scales, and actuators from one place. By reducing equipment touches and automating code changeovers, the system minimizes the potential for human errors, leading to enhanced accuracy and improved overall productivity.

-

Is the MPERIA Controller scalable to accommodate future growth?

Absolutely! The MPERIA platform is designed to scale with your business needs. Whether you want to add equipment to your production line or expand to multiple plant locations, the MPERIA Controller can handle it without compromising performance.

-

Can MPERIA work with XML?

Yes, MPERIA can work with XML (Extensible Markup Language). XML is a widely used data format for exchanging and storing structured information. MPERIA’s flexible architecture allows it to handle various data formats, including XML. By leveraging its capabilities, you can seamlessly integrate XML data into the MPERIA Controller for automated message creation, product identification, serialization, and other marking processes. This compatibility with XML ensures that you can efficiently utilize your existing data sources to streamline your marking and coding operations with MPERIA.

The MPERIA Controller is a cutting-edge solution designed to streamline marking and coding operations. It allows you to switch messages in seconds, centralize coding control, and improve mark quality on your production lines. By offering a user-friendly interface, automation capabilities, and seamless integration, the MPERIA Controller significantly enhances efficiency and reduces errors.

Yes, absolutely! The MPERIA Controller is highly flexible and can integrate smoothly into your current environment. No custom software or server hardware is required, ensuring seamless connectivity with your enterprise systems and legacy equipment, regardless of the manufacturer.

The single user interface of the MPERIA Controller streamlines equipment control, making it easy for operators to manage printers, barcode readers, vision systems, scales, and actuators from one place. By reducing equipment touches and automating code changeovers, the system minimizes the potential for human errors, leading to enhanced accuracy and improved overall productivity.

Absolutely! The MPERIA platform is designed to scale with your business needs. Whether you want to add equipment to your production line or expand to multiple plant locations, the MPERIA Controller can handle it without compromising performance.

Yes, MPERIA can work with XML (Extensible Markup Language). XML is a widely used data format for exchanging and storing structured information. MPERIA’s flexible architecture allows it to handle various data formats, including XML. By leveraging its capabilities, you can seamlessly integrate XML data into the MPERIA Controller for automated message creation, product identification, serialization, and other marking processes. This compatibility with XML ensures that you can efficiently utilize your existing data sources to streamline your marking and coding operations with MPERIA.

[wpforms id=”10226″ title=”true”]