Corrugated boxes come in a variety of styles and variables. Showing your packaging specialist the item you are packing, how it is shipping, and how it is being stored will give them a good roadmap to determine what style and strength you will need. Check out the following topics covering measuring the box, strength, style, material, and fluting.

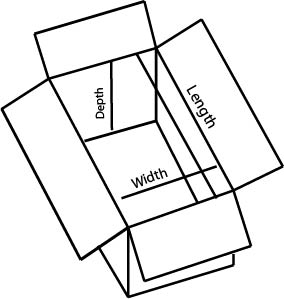

Box Measurement

Measure a box using the inner dimensions of an assembled box – Length (L) x Width (W) x Depth (D). Looking at an assembled box, the longer of the two sides is considered the length, the shorter of the two sides is the width, and the side perpendicular to the length and width is the depth of the box.

The “Manufacturer’s Joint” is where the two ends of the side panels meet to form the box. At that point, the panels are fastened together with tape, staples (double or triple wall) or glue (single wall). This description applies to regular slotted shipping cartons (RSCs). The side panel thickness and content weight determine the type of seal used for the manufacturer’s joint.

Strength

The strength of a corrugated box starts with its material. A corrugated sheet consists of two major components – linerboard and medium. Linerboard is the flat paper that covers both sides of the sheet and the medium is the “fluted” or arched paper found between both liners. The flute, when anchored to the linerboards with a starched based adhesive, resists bending and pressure from all directions. When placed vertically on its ends, the flutes form vertical columns, capable of supporting considerable amounts of weight.

Material

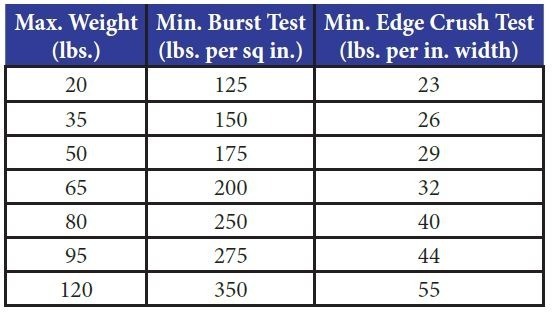

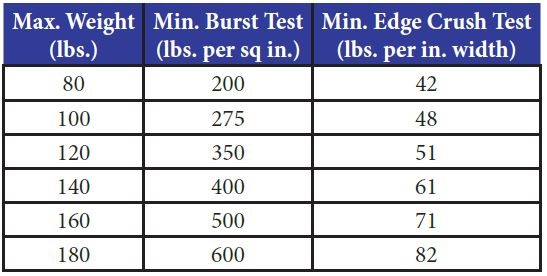

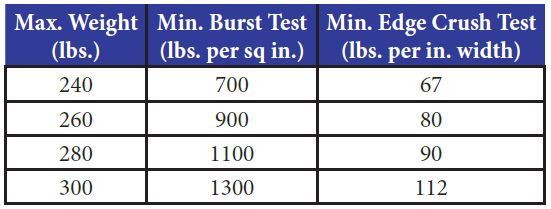

The amount of virgin pulp fibers and the length of those fibers in a corrugated sheet substantially contribute to box strength. For example, the difference between a 200# test box and a 275# test box is that the latter has more pulp fibers in its corrugated linerboard. The 200# test box is rated to hold up to 65 lbs. of box and contents while the 275# box can hold up to 95 lbs. A 350# test box is rated to hold up to 120 lbs. of box and contents. The following chart shows Bursting Test and Edge Crush Test performance standards of corrugated box liners based on the combined weight of a box and its contents.

Fluting

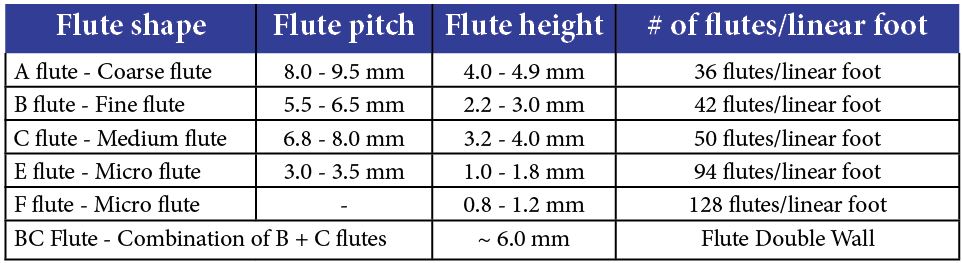

Flutes come in five basic heights and shapes – the most common are “B-Flute”(used for die-cut boxes) and “CFlute (used for RSCs). B-flute is compressed and appears thinner, but don’t be fooled. It is made with more paper to provide stronger side wall protection from blows and punctures. C-flute is taller, with more air space, but offers enhanced stacking strength. For excellent graphic reproduction, consider E-flute.

Popular Box Styles

Regular Slotted Carton (RSC)

Full Telescope Design (FTD)

Multi-Depth Width (MDW)

Double Cover Carton (DC)

Full Overlap Slotted (FOL)

One Piece Folder (OPF)

Five Panel Folder (FPF)

Snap Bottom Carton (SBC)

Wall Thickness

Singlewall Corrugated

This grade is used for lighter applications. Multiple light-weight objects work great for this box.

- one corrugated medium

- a total of three paper layers

Doublewall Corrugated

This grade is used for heavy applications, particularly in packaging for export and is excellent for stacking heavy items.

- two corrugated mediums

- an inner liner between the two mediums

- a total of five paper layers

Triplewall Corrugated

Looking for maximum strength? This is your board!

- total of seven paper layers

- used for very heavy industrial applications

- semi-bulk commodity bins, and many other uses

- excellent for stacking heavy items

Flute Size

Generally, larger flutes provide greater strength and cushioning, while smaller flutes have better printability and foldability. Flute profiles can be mixed and matched within the same piece of combined board, to manipulate printability, compression strengths, cushioning strengths and the total thickness of the board. For instance, CE double wall gets its durability from its C-flute layer, while the E-flute gives it a smoother printing surface.

-

A Flute: Good stacking and protection

A-Flute, the original flute, is the highest flute size, and therefore, when combined with an inner and outer facing, is the thickest. With 36 flutes to the foot, A-Flute makes the most of corrugated’s cushioning and stacking properties for fragile and delicate items. A-Flute offers excellent stiffness qualities and short column crush resistance.

-

B Flute: Good puncture resistance, great for can goods and displays – very good common grade

B-Flute, the second flute size adopted by the corrugated industry, has lower arch heights than A and more flutes per foot (50). This means that the medium contacts and supports the liners at a greater number of points, providing a stiff, flat surface for high quality printing and die cutting and with excellent crush resistant properties. B-Flute is also preferred for high speed, automatic packing lines and for pads, dividers, partitions and other forms of inner packing. Complex die cuts and beverage trays are excellent applications for B-Flute as are can cases, wraparound blanks, glass-to glass packs and slipsheets. B-Flute is generally combined with light weight liners but can be used with heavier facings if the need arises.

-

C Flute: Good stacking/protection, most common grade, good for glass, furniture & dairy

C-Flute came along next to split the difference between A and B Flutes. With 42 flutes per foot, it’s thinner than Aflute, thicker than B, and offers good cushioning, stacking and printing properties. C-Flute is by far the most widely used flute size. An estimated 80% of today’s corrugated containers are made of C-Flute board.

-

E Flute: Lightweight fine flute, superior printing surface, excellent for custom die-cut boxes

E-Flute has the greatest number of flutes per foot at 94 which gives it the greatest crush resistance and the flattest surface for high quality printing applications. The thin board profile of E-Flute (it is one-fourth the thickness of CFlute) reduces box size and saves storage space. Because of its thin profile and excellent cushioning properties, EFlute can often substitute for conventional folding cartons or solid fiber containers. Examples of E-Flute applications include boxes for cosmetics, fragile glass and ceramic items and delicate instruments. Another growing end-use is for pizza boxes where the retailer wants a cost effective container with good graphics and excellent product protection.

-

F Flute: Extra thin

F-Flute, the newest flute, is just a little more than half the thickness of E-Flute and is the newest growth segment in the corrugated industry. The idea behind the new flute, originally developed in Europe, is to make packages with lower fibre content. With F-Flute, converters can reduce the total amount of fibre in the packaging, thereby creating a more rigid box with less solid waste going into landfills. In Europe, F-Flute is being used for specialty packaging, point-of-purchase displays, jewelry and cosmetic packages and shoe boxes. In the U.S., the McDonald’s Big Mac clamshell in F-Flute has received great attention. Dairy Queen, too, is using the F-Flute clamshell for its “Ultimate sandwich” and its hot dogs.

The most common fluting companies will see is b-flute. It is what most RSC cartons are made of and the standard master carton in the industry. But, it is a great piece of information to know when considering printability, carton stacking, display and more.

[wpforms id=”10226″ title=”true”]